-

amargears@gmail.com -

+91-9814088596

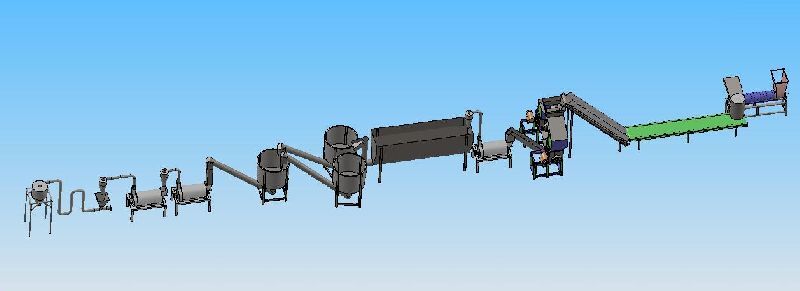

Pet Bottle Washing Line

Contact Us

Amar Industrial Corporation

C-39, Guru Ram Dass Road, Dhandari Kalan, Dhandari Kalan, Ludhiana, Punjab - 141010, India

Mobile : +91-9814088596

Phone : +91-161-5085590

Fax : +91-161-5027590

Amar Industrial Corporation is one of the trusted Manufacturers and Exporters of Pet Bottle Washing Lines. These Pet Bottle Washing Lines are efficiently designed by the experienced engineers with brief specifications that support clients to smoothen up their work. These can be availed at reasonable prices and within a stipulated timeframe.

Range :

|

|

Special Features :

|

|

Specifications

| Warranty | 1year |

| Product Name | Pet Bottle Washing Line |

| Brand Name | Amar Gears |

| Range | Vibrator,Cold Washer,Hot Water Tank With Steam Coil,Cold Water Tank,Floatation Tank,Bottle Crusher. |

| Feature | Reasonable designs,Simple & effective functioning,Efficiently cleaned,Safe for operations. |

| Place Of Origin | Ludhiana |

| Min. Order Quantity | As per client requirement |

Additional Information

| Payment Terms | T/T |

| Delivery Time | 3 Month (Min.) |

Specifications

| Bottle crusher | Equipped with 6 rotating & 2 fixed blades |

| Feeding screw conveyor | Transports flakes to vibrator |

| Vibrator | Equipped with metal detector |

| Cold washer | Flakes are efficiently cleaned, rubbing against each other inside inclined drum with blades on rotor |

| Floater | Separates the material according to their density Pet sinks to bottom and is discharged by a screw conveyor Remains of caps and rings floats on top and are removed by rotating shovels |

| Hot water tank with screw conveyor | Designed with agitator fitted with 5 H.P. Geared motor (30-35 R.P.M.) fitted with S.S. 304 steam coil to heat water upto 180 0C. Agitator churns the material and removes glue and labels from pet flakes |

| Centrifugal spin dryer | The wet flake are dewatered in vertical conical spin dryer the flakes are dried to 2% of humidity |

| Cyclone with steam screw conveyor | The material from spin dryer enters to cyclone & it bypass air and feeds the material to steam screw for final output of dried flakes ready for further process |

| Power consumption | 35 KW |

| Process capacity | 20 mt/day |